- QThe 2 Role of Blackbody In Thermal Camera Temp Measurement

A All objects in nature whose temperature is higher than absolute zero (-273.15℃) have the ability to continuously radiate, absorb and emit red radiation. The electromagnetic waves radiated out are different in each band and have a certain spectral distribution. This spectral distribution is related to the properties of the object itself and its temperature, so it is called thermal radiation. In order to study the laws of thermal radiation that do not depend on the physical properties of a substance, physicists have defined an ideal object, a black body, as the standard object for the study of thermal radiation. The so-called blackbody refers to the incident electromagnetic waves are all absorbed, neither reflected, nor penetrating. According to Kirchhoffs radiation law, the ratio of energy to absorption of an object in thermal equilibrium has nothing to do with the property of the object itself, only with the wavelength and temperature. According to Kirchhoffs radiation law, at a certain temperature, a blackbody is the body with the greatest radiation power, with a surface emissivity of 1. Therefore, in infrared thermal imaging, the blackbody is used as a reference, which is equivalent to a zero point. The emissivity is defined as the ratio between the radiation capacity of an object and that of a blackbody at the same temperature.

- QWhy do the temperature measuring products need to be corre

A (1) The correction of baffle (equivalent to the built-in blackbody) mainly solves two problems: The first is to eliminate the temperature drift and ensure the accuracy of temperature measurement. The second is to show that the temperature will deteriorate without baffle correction and the picture will show obvious noise. (2) no baffle products is the main one in order to solve the problem of picture pause baffle calibration, which solve the problem of lost frames, secondly it is to solve the problem of the noise of the damper temperature (sound), thirdly it is baffle life: mechanical life is short, life of baffle to baffle the service life of the product have been affected, four is: volume damper products limited to baffle size, no baffle product size can be smaller. (3) Baffle products are mainly used for imaging, blast furnace with many baffle, dust will affect the baffle life

- QWhat kinds of thermal imaging products do we have, their

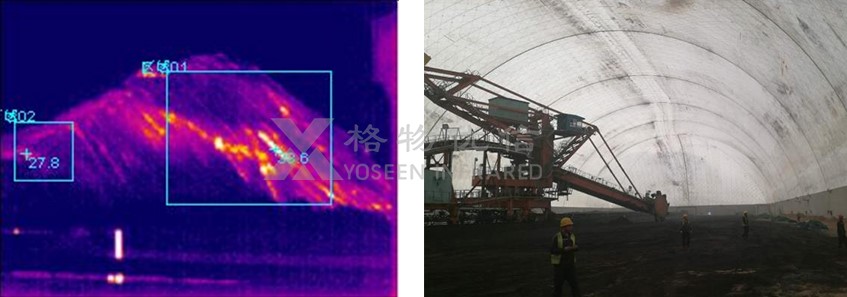

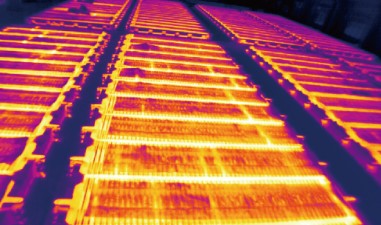

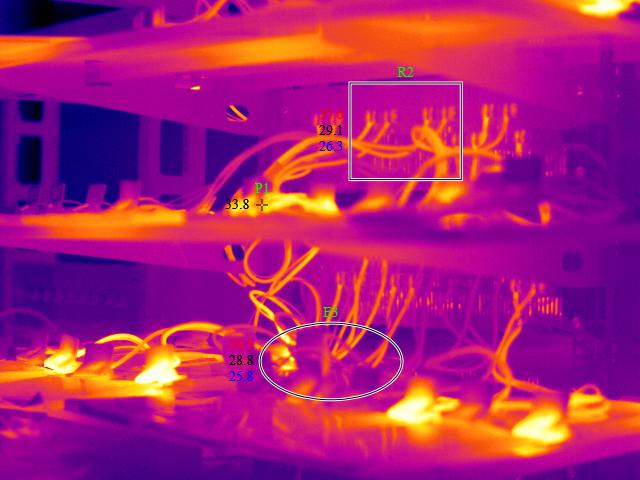

A (1) Single Infrared Cameras Typical I ndustrial A pplications of E ach P roduct: YOSEEN-X Series (Standard): It can be integrated or supplied to the integrator, or installed in a variety of large head cover, and applied in warehouse monitoring (high cost, but also applied), power monitoring, security, ladle monitoring (X is preferred, with more complete functions and more interfaces than M) and other fields. YOSEEN-X (Rail Transit) Series: 50Hz, mainly used in rail transit industry, such as wheel detection, electrical joint detection, etc. YOSEEN-M Series (Standard) : Compared with X, it is small in size and can be supplied to integrator by single product. Customers who have requirements on size are installed in small head cover and applied in warehouse monitoring, power monitoring, security protection, metallurgy and other fields (X and M are essentially the same in application fields). YOSEEN-SP Series: It is supplied to customers with low budget, little temperature change within 1s of monitoring target and low bandwidth requirement, and applied in electric inspection, robot, forest fire prevention, etc.. YOSEEN-AP Series : To customers who cant use the network on site and want to simulate video transmission, few customers want it now. Blast F urnace M onitoring: It is used to monitor the surface of metallurgical and iron-making high charge. It needs to be equipped with cooling device, which is usually supplied by customers themselves. We provide single product. Airborne Thermal Camera: equipped with uav, used for power transmission line inspection, oil pipeline inspection, etc. High Speed Infrared Thermal Camera: single infrared product is supplied to the integrator for detecting fast moving objects (for angular velocity). It is mainly used in the rail transit industry, such as detecting the temperature of train wheels and the catenary of power supply. YOSEEN - Imaging Series (network imaging) : customers need low-cost , only imaging does not require temperature measurement, can not guarantee the accuracy of temperature measurement, prison, security and other industries. (2) Single Cylinder + Shield Typical Industrial Applications of Each Product: Common Single Cylinder Thermal Camera: indoor and outdoor monitoring, germanium chip or not, used for warehouse monitoring, security, nondestructive testing, etc. Explosion-Proof Single Cylinder Thermal Camera: used in explosion-proof situations, such as monitoring of hazardous chemicals, coal pile monitoring, hazardous waste disposal monitoring, etc. (3) Dual Lights Thermal Camera + Shield Typical Industrial Applications of Each Product: Big Ball Thermal Camera: large volume, can be installed with electric lens, can be lifted or installed, used for robot, security, warehouse monitoring, power monitoring, etc. Small Ball Thermal Camera: small size, can only be installed without thermalization lens, can be lifted or installed, used for robot, security, warehouse monitoring, power monitoring, etc. T-Type Thermal Camera: used in scenic spot monitoring, power monitoring, security, plant monitoring, etc. Cabin Type Thermal Camera: used for forest fire prevention, maritime affairs, frontier defense and other monitoring. Explosion-Proof Dual Lights Thermal Camera: used in coal mine monitoring, chemical monitoring, petrochemical monitoring, etc. Card Type Thermal Camera: used in power distribution cabinet monitoring and other large consumption, low monitoring requirements, low cost of the industry. (4) Portable Thermal Camera Typical Industrial Applications of Each Product: Hand-held Infrared Thermal Camera: underground mine, search and rescue, hunting, building maintenance inspection

- QIs there an interface for data access?

A Based on network SDK to control and access device data, the dual-lights thermal camera with cradle head provided by us supports dual-channel RTSP and infrared RTSP, including only infrared images. (no need to use SDK to access) infrared temperature data, including temperature and image. (Must be accessed using the SDK).

- QCommon external interface, Ethernet, relay, analog video, po

A (1) Ethernet: 100/1000m is supported, which can transmit video stream and temperature stream. The video stream only displays the characteristic temperature, which cannot be used for temperature analysis. The temperature stream can display the global temperature, which can be used for temperature analysis. (2) Relay: one relay output is only used as a switch (no voltage output) to connect the acousmo-optic alarm device. When the monitoring target reaches the alarm temperature, the relay closes and emits an acousmo-optic alarm. (3) Analog video: No network is needed and the display can be directly connected. Only the infrared picture and characteristic temperature are displayed, not the temperature of each point. (4) Serial ports: supports RS485, can do simple configuration and control of equipment, such as switch palette, capture, video and other commands, and analog video, general industrial equipment, with more to stability requirement is higher, Ethernet has a time delay, industrial less, a serial port can be extended many devices (such as WiFi). (5) Power supply: support 9-15V power supply, generally use 12V power adapter, can be customized 5V.

- QGermanium chip window usage scenario?

A Germanium chip should be used when the thermal camera needs to be installed in the protective cover, especially in outdoor or explosion-proof and dust-proof situations.

- QThe selection of the shield, the difference between the shie

A (1) Big ball machine: Used in warehouse monitoring, power monitoring, security, robot patrol and other scenarios; Horizontal rotation can be 360, vertical rotation can be -15 (overlooking) ~ +90 (looking up), 256 preset positions can be set, 6 cruise routes, each can be set 16 preset positions; Large volume, internal space 150*70*60mm, infrared lens maximum available non-heating 35mm, electric 25mm, visible light pixel 2 million 30 times, germanium chip size 50*3mm; (2) Small ball machine: Used in warehouse monitoring, power monitoring, security, robot patrol and other scenarios; Horizontal rotation can be 360, vertical rotation can be -20 (overlooking) ~ +90 (looking up), 256 preset positions can be set, 6 cruise routes can be set, each can set 16 preset positions; Small volume, internal space 85*46*44mm, lens maximum available non-thermal 19mm, visible light pixel 2 million 20 times, germanium chip size 33.5*2mm; (3) T-type (high cost of Feiyue) : It is applied to scenic spot monitoring, plant monitoring, power monitoring, robot patrol inspection, security and other scenes; Horizontal rotation can be 360, vertical rotation can be -90 (overlooking) ~ +90 (looking up), 200 preset positions can be set, 8 cruise routes can be set, each can set 10 preset positions; High precision head, expensive price, gear transmission, high stability, live hand does not move, internal space is about 200*70*120mm, customizable, lens unlimited, germanium sheet size 60*2mm; (4) T-type (low cost of Anxing) : Used in scenic spot monitoring, plant monitoring, power monitoring, robot patrol inspection, security and other scenes; Horizontal rotation can be 360, vertical rotation can be -90 (overlooking) ~ +90 (looking up), 128 preset positions can be set, 8 cruise routes, each can be set 32 preset positions; The belt carries the cradle head with slightly lower stability, the electrified hand can rotate, high-frequency vibration, relatively low price, internal space about 140*70*90, the largest 50mm electric lens, germanium chip size 50*3mm; (5) Cabin type: applicable to forest fire prevention monitoring, distribution power station monitoring, offshore oil platform monitoring, frontier monitoring and other outdoor scenes; Horizontal rotation can be 360, vertical rotation can be -60 (overlooking) ~ +80 (looking up), 200 preset positions can be set, 8 cruise routes can be set, each can be set 10 preset positions; The price is relatively expensive, the internal space is about 250*100*130mm, customizable, lens unlimited, germanium chip size 110*6mm; ( 6 ) Explosion-proof double cylinder s : used in petroleum, chemical industry, oil depot, coal mine and other inflammable and explosive scenes; Horizontal rotation can be 360, vertical rotation can be -90 (overlooking) ~ +90 (looking up), 256 preset positions can be set, 8 cruise routes can be set, each can set 80 preset positions; The internal space is 120*120*220mm, normal lens can be used, germanium sheet size is 80*8mm; ( 7 ) Explosion-proof single cylinder: it is applied to the monitoring of hazardous chemicals, coal pile and hazardous waste disposal; Fixed installation, horizontal and vertical Angle can be adjusted by universal joint; This type of protective cover has a large internal space (customizable), which can be installed with M or X machine. Generally, the front protection net is not installed, which can be used with bracket/universal joint. Germanium sheet is applicable: 80*8mm (the size of opening can be customized). ( 8 ) Common single cylinder: used in warehouse monitoring, security, nondestructive testing and other scenarios; Fixed installation, vertical direction Angle can be adjusted; The inner space of this shield is small, so only M machine can be installed. The maximum manual lens is 30mm. Germanium sheet size can be customized according to the size of the hole, and germanium sheet can be installed without.

- QOur existing cradle head types, different cradle head charac

A (1) Characteristics and applications of different headsets (see Question 5); (2) The operating temperature of cradle head products shall not exceed 50℃, and that of conventional products shall not exceed 60℃ (the maximum for railway machines shall not exceed 70℃). (3) The machine installed in the ball machine will remove the back shell and directly lead out for installation; If the ball machine outlet way has the bottom outlet and the side outlet, the bottom outlet generally connects all the interface line with a hose, generally is the straight head way, the side outlet generally uses the airlock socket to lead out all the lines, has the straight head and the elbow two ways. Machines other than ball machines can be installed in a complete machine.

- QAdvantages of infrared thermal imaging and other imaging tec

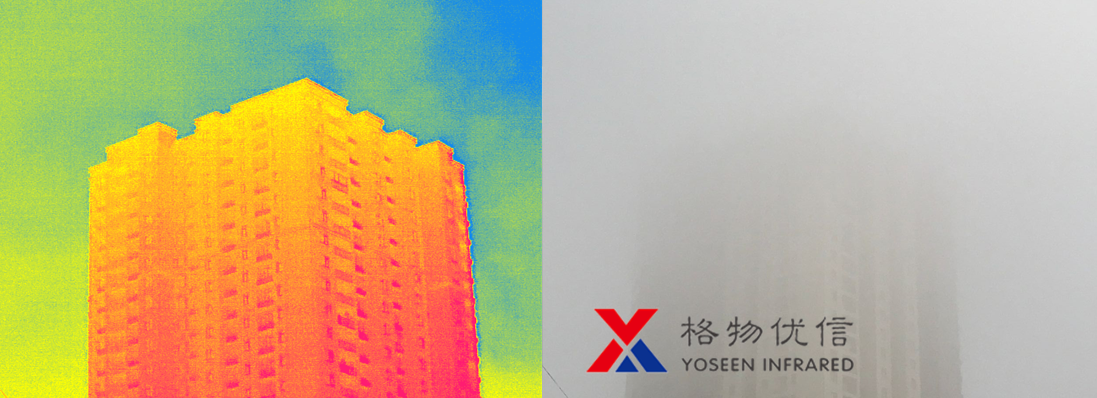

A Advantages of infrared thermal imaging Technology: lNot affected by light, no lighting, day and night imaging; lReal-time display of the temperature of each point within the detection range; lStrong penetrating ability, able to penetrate smoke, high visibility in harsh weather and environment; lCan track temperature anomaly and alarm automatically.

- QWhat are the similarities and differences between infrared t

A (1) The infrared thermal imaging temperature measurement technology adopts the non-contact temperature measurement mode, and the detector adopts amorphous silicon or vanadium oxide to passively receive the infrared ray emitted by the object. The temperature measurement has high accuracy, high speed (50Hz/s), wide range and long distance (several kilometers), which can accurately obtain the large-area temperature distribution image in a short time. (2) Common temperature measurement techniques: point thermometer and thermopile, mainly used for temperature difference and average temperature in small areas, The general resolution is 88, 1616, 3232, etc., and the temperature measurement accuracy is limited.

- QWhat does image flip mean?

A (1) Rotation: The image is rotated clockwise with the center of rotation as the center point of the picture. At present, the picture can only be rotated 180 instead of 90 and 270, because the infrared picture has a 4:3 ratio and cannot be rotated 90 and 270. (2) Mirror image: it means to rotate 180 around the horizontal or vertical center line. (3) In order to maintain the aspect ratio of the front end (thermal camera), the front end only supports 180 rotation or mirror image at present.

- QWhat is the meaning of frame rate adjustment, data rate, sen

A (1) Frame rate: refers to the number of images taken, processed and displayed by the thermal camera within one second, that is, the frequency of temperature update. (2) Data rate: It affects the frame rate of data collected by the current thermal camera. (3) Send rate: It affects the frame rate of temperature data sent by the current thermal camera.

- QIP setting for direct connection between thermal camera and

A (1) Direct connection: After connecting the thermal imager with the computer, the IP of thermal camera should be found in the software selection tool of thermal camera, and then the IPV4 of the computer should be set as the IP of the same network segment with the thermal camera, but not repeated with the default IP address of the thermal camera. (2) Router: under the premise of ensuring that thermal camera, router and computer are in the same IP segment, or all three are dynamically allocated IP, they can be directly connected via wireless or wired channels.

- QWhat is the device port number?

A The network protocol provided by the device: ports are as follows Control port 55502 Temperature flow port 55503 Single frame temperature port 55505 Video streaming port 55506 Mixed flow port 55507 (card machine specific) RTSP port 554 #SDK is a device-side + client, 2-side structure. Our devices are not cloud devices. Its just a network device. # Device access issues across networks. There can be a server in the middle or a simple port mapping. Not supported by the SDK # Use device data and follow SDK documentation; You need to look at ports for external access.

- QIs dual lights thermal camera controlled via RS485 or networ

A Dual lights thermal camerasupports both network and RS485, generally using network control, but some customers need to control themselves, can use RS485, default dual lights thermal camera products do not support RS485.

- QHow to synchronize multiple thermal cameras shooting togethe

A If it is to install multiple thermal cameras, we have software to control multiple devices, but it is difficult to strictly synchronize the time, and there will be second-level delay in general monitoring. Multiple sets of shooting can be started at the same time, as detailed in the SDK documentation.

- QDoes the machine have control over the external port to star

A We currently do not have such external ports, which need to be controlled over the network.

- Qhe temperature is sometimes inaccurate, can adjust the envir

A The temperature drift parameter can be adjusted, but not too much.

- QDoes the device support multi-point access?

A Video streaming supports one to many, while temperature streaming supports one to one.

- QDoes the SDK support C# language?

A Support C# (Sharp), C++, C language, JAVA.

- QHow to explain the blur of a single temperature scene observ

A When the temperature distribution of the scene is single, fog or pitting points will appear in the picture, which belongs to the inherent noise of the detector, and will be very obvious after DDE is turned on and enhanced. DDE is used to adjust the detail enhancement, and the gain can be understood as to adjust the temperature amplification factor. The algorithm will give an amplification factor according to the scene temperature difference. When the scene temperature is relatively single, the temperature is mapped to 256, and the noise will be obvious.

- QHow to connect the electric source of the thermal camera?

A It can be directly connected to 12V power supply, or 220V to 12V power adapter

- QIs there a relationship between temperature accuracy and res

A There is no relationship between the two. The higher the resolution, the more pixels will cover the surface of the same size, and the more pixels, the higher the definition.

- QWhat does the palette mean? Which applications require which

A (1) Each pixel has a gray value of 256 levels, and each pixel is artificially endowed with a color value, which is called pseudo-color, that is, the palette we use. (2) Iron red palettes for general use, black and white palettes for security, and rainbow palettes for medical use.

- QProduct working temperature range, IP protection level and p

A (1) Operating Temperature Range Single infrared thermal cameraswithout shield and heat sink: -10 ~ 60℃ (railway machine can achieve -10 ~ 70℃) With cover: -20 ~ 50℃, generally without fan (2) Product Protection Level lSingle thermal cameras without cover: IP54 lSmall Ball Type, T Type, Cabin Type thermal camera: IP66 lBig Ball Type, Explosion-proof Dual Lights, Cylinder Type thermal cameras: IP67 lExplosion-proof single infrared thermal camera: IP68 (3) See the X384 test report for details

- QWhat is the temperature measurement range of our infrared th

A (1) Temperature Measuring Ranges Range Code Temp Measuring Range Range Code Temp Measuring Range 000 Imaging Type 1000 100℃-1000℃ 150 -20℃-150℃ 1200 120℃-1200℃ 300 0℃-300℃ 1600 160℃-1600℃ 600 60℃-600℃ 152 -20℃-150℃(Special for Railway) 615 -20℃~150℃,60℃~600℃(double) 302 0℃-300℃(Special for Railway) 800 80℃-800℃ (For blast furnace) 050 0-50℃(Human body temperature) (2) The difference of temperature measuring range and whether bigger is better The purpose of choosing different temperature measuring segments is to adapt to different temperature measuring objects and improve the accuracy of temperature measuring. The larger the temperature measuring range is the better. For example, the imaging effect of low-temperature objects in the high temperature range will be poor, so the appropriate temperature range should be selected according to the actual temperature measuring objects. (3) Select the appropriate temperature range According to the user needs to accurately measure the maximum temperature, such as forest fire prevention, 150℃ can alarm, temperature range does not need to choose a higher temperature range.

- QHow many resolutions do we have for infrared thermal cameras

A (1) Resolution of infrared thermal camera 160 * 120384 * 288640 * 4801024* 768 ( 2 ) Mainstream resolution 384 * 480 * 288 and 640. ( 3 ) How to choose the resolution A customer is not sensitive to the cost budget, generally recommend 640 * 480, 2 it is although there is a limit customer costs, but we need to choose according to actual application to products can meet the needs of user, if 384 within the cost, also can meet the need, can choose, but if you cant meet the demand, need to recommend 640, all customer actual application demand, the precondition of the situation to the customer.

- QAbout temperature measurement accuracy of infrared thermal c

A (1) Factors Affecting Temperature Measurement Accuracy Temperature measurement distance: The farther the distance is, the smaller the image of the temperature measurement object will be. The infrared attenuation received will be nonlinear. The ratio of center attenuation and edge attenuation is different, and the temperature measurement accuracy will be affected. Environment: rain, snow, fog, dust and other harsh environments, due to unclear environmental factors (if not know how much fog), temperature measurement accuracy can not be required according to the standard accuracy. Target temperature: Accuracy beyond the temperature range of the machine cannot be guaranteed. Working temperature of thermal camera: it has influence. For example, when the working temperature of thermal camera is relatively high, the error of measuring low-temperature object is larger (2) Industries with H igh A ccuracy R equirements Human body temperature measurement (schools, hospitals, etc.), generally 0.4℃ or 0.5℃; Scientific research (plant and animal experiments); The application of high temperature measurement accuracy is mainly related to people.

- QType of infrared detector, and the meaning of pixel size and

A (1) Infrared detector types: vanadium oxide (long-range, large-lens imaging), amorphous silicon, we use amorphous silicon (ULIS, France). (2) Pixel size: the size of a single pixel, usually 17 m. (3) Working band: the infrared band that can be received by infrared thermal camera. The working band of our product is 8-14 m.

鄂公网安备 ******号

鄂公网安备 ******号